1. Skip-tooth design structure:disperses cutting force, easily achieves high spindle speed and high feed depth,skip-tooth staggered tooth forming design, reduces cutting resistance, and improves tool life. One cut molding, high smoothness, higher efficiency than three teeth, and better rigidity than full teeth. 2. Increase the helix angle, both internal and external threads can be machined. 3. Balzers Nano Coating:Nano level coating reduces cold welding phenomenon, improves wear resistance by

Product features:

1. Skip-tooth design structure:disperses cutting force, easily achieves high spindle speed and high feed depth,skip-tooth staggered tooth forming design, reduces cutting resistance, and improves tool life. One cut molding, high smoothness, higher efficiency than three teeth, and better rigidity than full teeth.

2. Increase the helix angle, both internal and external threads can be machined.

3. Balzers Nano Coating:Nano level coating reduces cold welding phenomenon, improves wear resistance by more than 50%, and is suitable for high-speed cutting.

4. Walter equipment production in Germany:ensuring the geometric accuracy and consistency of cutting tools (error ≤ 0.005mm).

5. Japan imports Sumitomo tungsten steel materials.

6. Processing hardness:within HRC65

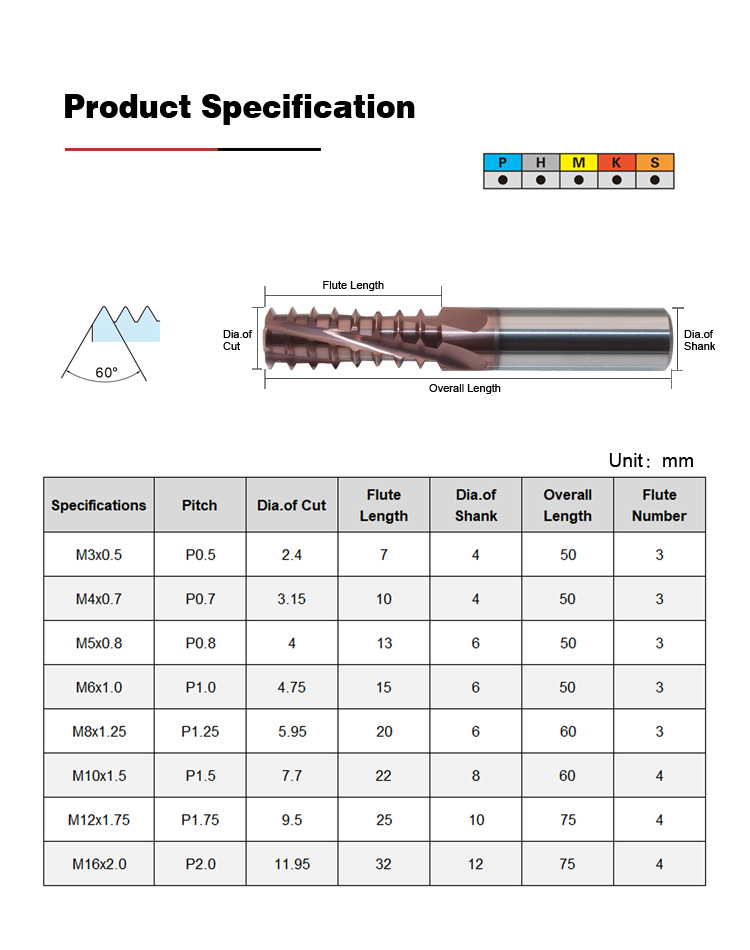

7.60 ° profile angle:Standardized design compatible with mainstream thread specifications, reducing adjustment time.

Applicable materials:

High hardness materials: stainless steel (such as 304/316) with HRC ≤ 60 °, titanium alloy (Ti6Al4V)

High temperature alloys: Nickel based alloys (Inconel 718) and quenched steels

Main purpose:

Specially designed for high-precision thread milling, it is particularly suitable for blind/through-hole thread machining of difficult to cut materials such as stainless steel and titanium alloys. It is widely used in the fields of automotive parts, aerospace precision parts, and energy equipment manufacturing.

Applicable scenarios:

1. Efficient thread forming for CNC machining centers.

2. Large aperture (M8 or above) or deep hole (3 times diameter or above) thread machining.

3. Batch production scenarios that require reducing the number of tool changes.

Contact: Scott

Phone: 18925556826

Tel: 0769-26998069

Email: info@sureweltools.com

Add: Room 230, Building 5, No. 24, Fuyin Road, Xiagang, Chang'an Town, Dongguan, Guangdong Province

Room 230, Building 5, No. 24, Fuyin Road, Xiagang, Chang'an Town, Dongguan, Guangdong Province

18925556826