Rod:Ultra fine particles 0.4 μ m Coating:AlCrN Spiral angle:45 ° Cutting hardness:Below HRC55 Cutting direction:radial/axial/inclined milling Cutting method:High speed large cutting depth

Product Name:Ultra fine particle tungsten steel coated high-efficiency end mill

Rod:Ultra fine particles 0.4 μ m

Coating:AlCrN

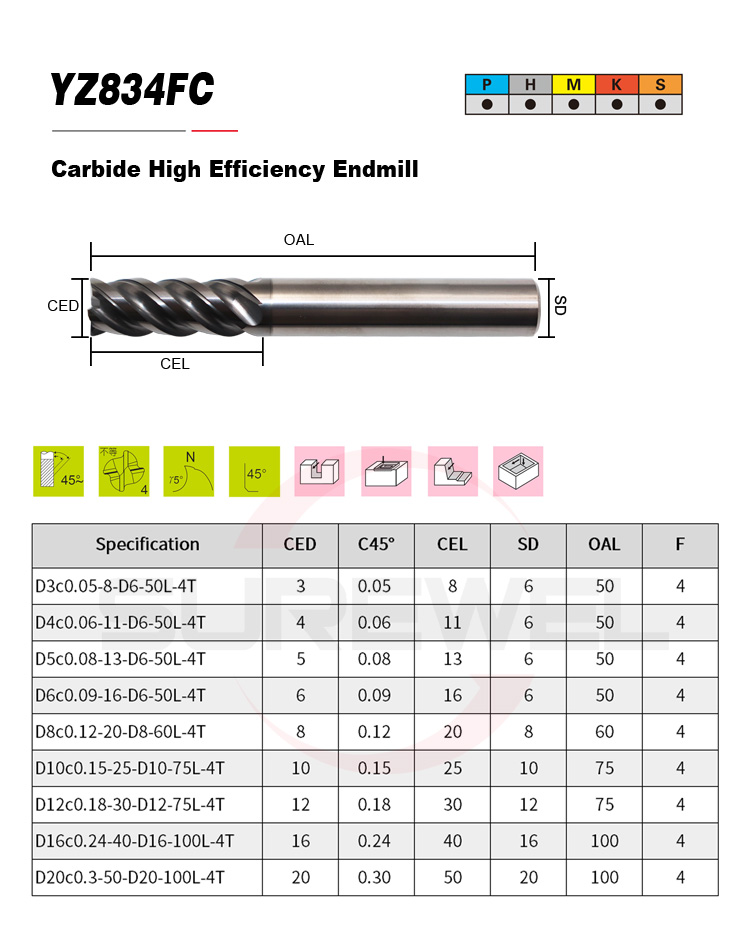

Spiral angle:45 °

Cutting hardness:Below HRC55

Cutting direction:radial/axial/inclined milling

Cutting method:High speed large cutting depth

一、Product features:

1. Ultra fine tungsten steel matrix: 0.4 μ ultra-fine particles enhance fracture resistance and blade sharpness.

2. Unequal cutting edge: By designing asymmetric tooth pitch to suppress vibration, cutting stability and metal removal rate are improved.

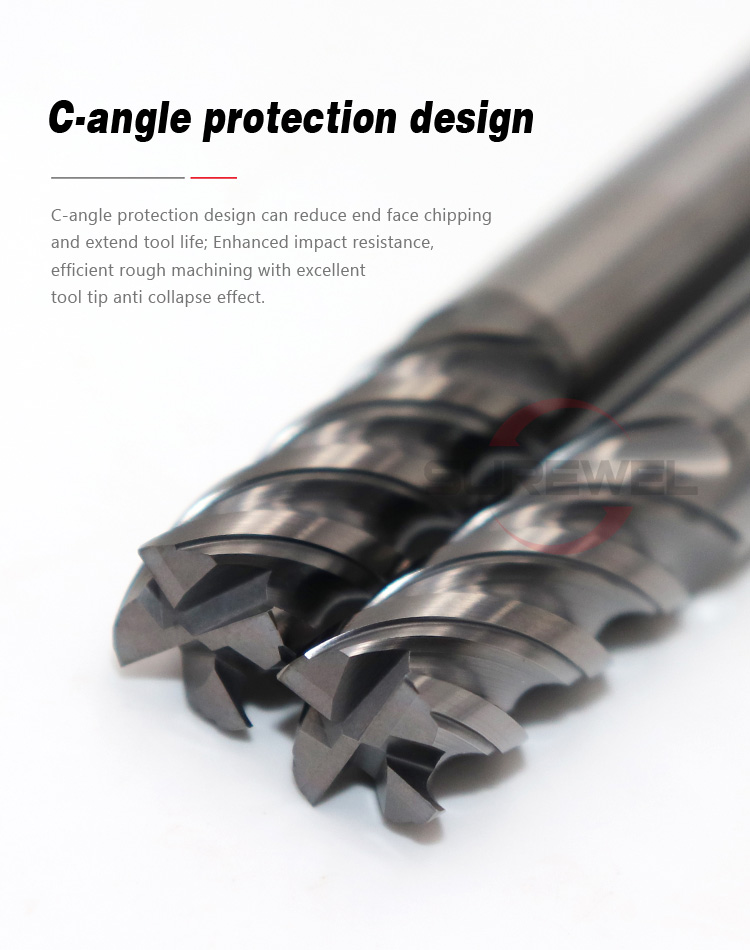

3. C-angle protection design can reduce end face chipping and extend tool life; Enhanced impact resistance, efficient rough machining with excellent tool tip anti collapse effect.

4. AlCrN coating: higher aluminum content than traditional AlTiN, heat resistance up to 1100 ℃, significantly reducing friction coefficient.

(A) The AlTiN coating also exhibits a decrease in hardness at temperatures below 900 ℃; The AlCrN coating can still maintain its hardness at a temperature of 1100 ℃. Even at high temperatures of 1100 ℃, the AlCrN coating can protect the tool substrate from oxidation.

(B) Due to the high red hardness of AlCrN coating, it can still maintain stable performance under extremely high thermal loads. Therefore, AlCrN coated tools have better machining performance than other types of coated tools, especially under high-speed cutting and dry (or quasi dry) cutting conditions.

二、Main application: Suitable for high-speed precision milling, suitable for multifunctional applications such as rough machining, medium machining, precision machining, drilling, high feed cutting, and dynamic milling. Especially skilled in rough and fine cutting applications of carbon steel, alloy steel, stainless steel and other materials with medium to low hardness; Groove machining, sidewall finishing, and contour cutting of difficult to machine materials such as titanium alloys, high-temperature alloys, and stainless steel.

三、Applicable scenarios: aerospace (processing of titanium alloy structural parts), mold manufacturing (high hardness steel parts), energy equipment (cutting of heat-resistant alloys) and other high-precision industrial fields.

Contact: Scott

Phone: 18925556826

Tel: 0769-26998069

Email: info@sureweltools.com

Add: Room 230, Building 5, No. 24, Fuyin Road, Xiagang, Chang'an Town, Dongguan, Guangdong Province

Room 230, Building 5, No. 24, Fuyin Road, Xiagang, Chang'an Town, Dongguan, Guangdong Province

18925556826